Key Information

Academic Supervisors: Prof R Johnston, Prof C Pleydell-Pearce and Dr Mark Coleman.

Industry Supervisor: Mr. Andrew Holwell

Expected Interview Date: Early May 2022

Background:

To achieve carbon dioxide emissions targets and reduce global warming, entirely new materials with capability to deliver high strength with low relative weight, are required for a range of industries. The carbon intensity of traditionally manufactured steel necessitates change to bring about a reduction in environmental impact, whilst maintaining material properties. This project will validate performance and equivalence of ‘low carbon economy steels’ to traditionally manufactured steels using advanced characterisation techniques.

Project Aims:

In developing new materials and to evolve existing industrial materials, it is important to understand the correlation between macroscale performance and microstructural composition.

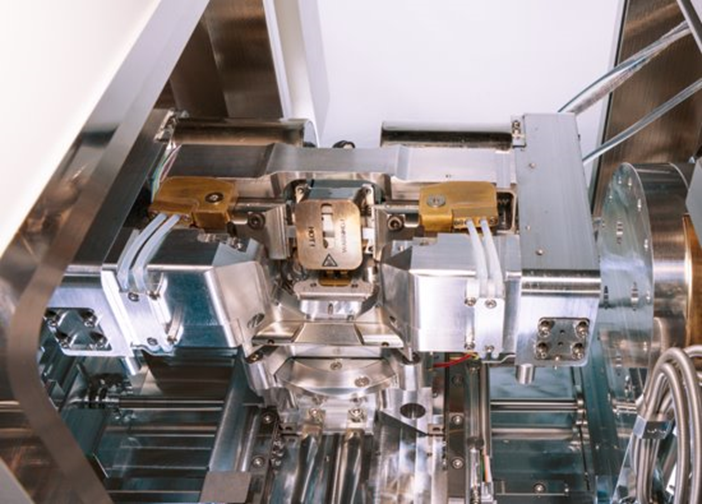

Up to now, there is little literature linking microstructural performance to macroscopic properties mainly due to the complexity of the experimental setup. For this purpose, Carl Zeiss Microscopy, the world’s largest microscope company, has developed an automated in situ heating and tension system based upon a field emission scanning electron microscope.

In addition to stress-strain curves, the system can monitor multiple regions of interest in real time with high resolution and perform automated energy dispersive spectroscopy (EDS), electron backscatter diffraction (EBSD) and digital image correlation (DIC) analyses, thus building up a time-resolved microstructural dataset of the sample.

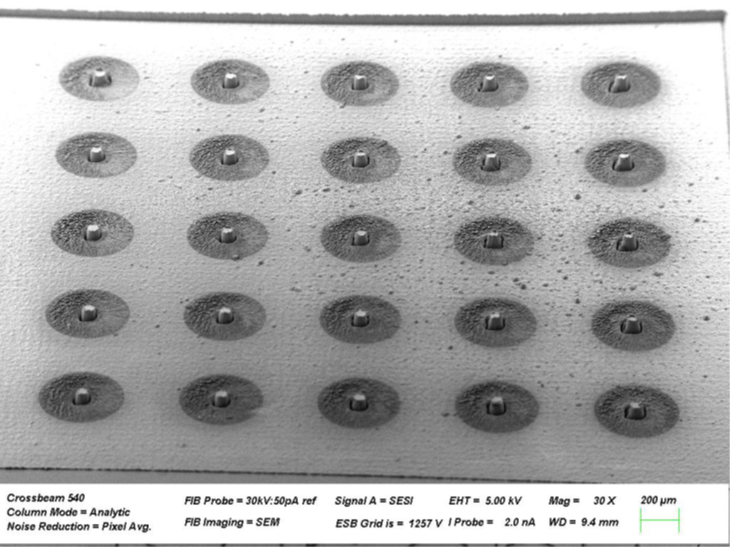

In this project, steel and alloy samples will be prepared at Swansea University and characterized by SEM, EDS and EBSD. The student will work collaboratively with Zeiss, traveling to the ZEISS offices in Cambridge, UK, (where ZEISS manufactures all its scanning electron microscopes), to work with the ZEISS materials research team to analyse samples with this new device. The aim being to understand the microstructural changes within the sample at elevated temperatures and applied force. Macroscopic stress strain data will then be correlated to microstructural characteristics of the materials to link performance and microstructure. In parallel, nanomechanical pillars of the same materials will be prepared at ZEISS through high-speed femtosecond laser ablation. Compression testing of these pillars will be compared with the in-situ SEM measurements to provide a separate validation of the material properties via a complementary method such as finite element modelling.

Figure 1: ZEISS in situ heating and tension rig

Figure 2: Array of pillars for micromechanical compression testing produced using femtosecond laser ablation and Ga FIB polishing.

COATED M2A recognises applicants have a variety of backgrounds with different educational and research experiences. We do not expect applicants to be proficient users of any techniques /equipment mentioned, at the time of application. Our focus is to upskill our participants and training will be provided.

COATED M2A in the Faculty of Science and Engineering is a Swansea University initiative which provides postgraduate research training in partnership with industry, providing access to world class laboratories and a wealth of academic and industry expertise. COATED M2A is committed to providing top quality research opportunities within an inclusive environment, funded by the Welsh European Funding Office (WEFO), the Engineering and Physical Sciences Research Council (EPSRC), Swansea University and Industry partners.

The Athena SWAN charter recognises work undertaken by institutions to advance gender equality. The College of Engineering is an Athena SWAN bronze award holder and is committed to addressing unequal gender representation. Applications from women and other under-represented groups are particularly welcomed. All applications will be anonymised prior to short listing.

Are you considering making an application and have questions you’d like answered? Come and have a 1-2-1 chat with us at our applicant surgeries (Link) . We encourage all applicants to review our hints and tips document found here

Sponsoring Company: Zeiss Microscopes, Software & Imaging Solutions ZEISS

Eligibility

Candidates must normally hold a minimum undergraduate degree at 2.1 level (or Non-UK equivalent as defined by Swansea University), or a combination of degree and equivalent experience to the same level.

Normally, we would expect candidates to have met the University’s English Language

requirements (e.g., IELTS 6.5 overall with 5.5+ in each component) by point of application.

Full eligibility can be found at https://www.materials-academy.co.uk/eligibility

Funding

Fees at UK rate and Stipend of £12,500, both for the period of one year.

For full details on funding eligibility, please refer to the Materials and Manufacturing Academy

(M2A) Website. Student Eligibility | M2A (materials-academy.co.uk/eligibility).

Candidates must have the legal right to live/work in the UK at the start of their studies (student visas do not apply)

Closing Date: 22nd April 2022

Start Date: 1st October 2022

Applications and informal enquiries about this studentship should be directed by email to:

M2A@swansea.ac.uk