research

Lester-Card, Edward, Application of Moringa Oleif xzera Seed Cake as a natural coagulant for the Removal of Oil from Model Oil-Water Emulsions. Lester-Card1, G Smith2, J. Widdowson1, C. Tizaoui1 , 3rd Euro-Mediterranean Conference for Environmental Integration EMCEI June 10-13th 2021 Tunisia. EMCEI – Euro-Mediterranean Conference for Environmental Integraion – Springer

Stewart, Daniel J.C, The production of high value pig iron nuggets from steelmaking by-products – A thermodynamic evaluation, July 2021

View

Taylor, T. KimaJ.Zhanga, K. Penney, D. and Yanagimotoa, J TRIP assisted press hardened steel by the anisothermal bainitic ferrite transformation. Journal of Materials Processing Technology Volume 289, March 2021, 116950

View

Potts, S.-J., Phillips, C., Claypole, T., Jewell, E. The effect of carbon ink rheology on ink separation mechanisms in screen-printing. 2020 Coatings, 10(10), art. no. 1008, pp. 1-17.

View

Wint, N., Malla, A.D., Cooze, N., Savill, T., Mehraban, S., Dunlop, T., Sullivan, J.H., Penney, D., Williams, G and McMurray, N.H. The ability of Mg2Ge crystals to behave as ‘smart release’ inhibitors of the aqueous corrosion of Zn-Al-Mg alloys. Corrosion Science, November 2020

View

Allman, A., Whiteside, J., Jewell, E., Griffiths, C., McMurray, N., de Vooys, A. Surface modification of Cr(III) packaging substrates for enhanced adhesion via citric acid processing. Surfaces and Interfaces. Volume 20, September 2020, Article number 100545

View

Davies, P.D., Davies, H.M., Watkins, I., Britton, D.A. The joining of gamma titanium aluminides via the powder interlayer bonding method. International Journal of Advanced Manufacturing Technology. Volume 109, Issue 7-8, 1 August 2020, Pages 2049-2054

View

Liu, X., Ouyang, M., Orzech, M.W. et al In-situ fabrication of carbon-metal fabrics as freestanding electrodes for high-performance flexible energy storage devices. Energy Storage Materials Volume 30, September 2020, Pages 329-336

View

Burkitt, D., Patidar, R., Greenwood, P., Hooper, K., McGettrick, J., Dimitrov, S., Colombo, M., Stoichkov, V., Richards, D., Beynon, D., Davies, M., Watson, T. Roll-to-roll slot-die coated P-I-N perovskite solar cells using acetonitrile based single step perovskite solvent system. Sustainable Energy and Fuels. Volume 4, Issue 7, July 2020, Pages 3340-3351

View

Daniel J.C.Stewart and Andrew R.Barron Pyrometallurgical removal of zinc from basic oxygen steelmaking dust – A review of best available technology. Resources, Conservation and Recycling, Volume 157, June 2020, 104746

View

Yates, H.M., Hodgkinson, J.L., Meroni, S.M.P., Richards, D., Watson, T.M Flame Assisted Chemical Vapour Deposition of NiO hole transport layers for planar perovskite cells. Surface and Coatings Technology. Volume 385, 15 March 2020, Article number 125423

View

Claypole, A., Claypole, J., Holder, A., Claypole, T.C., Kilduff, L. Rheology of high-aspect-ratio nanocarbons dispersed in a low-viscosity fluid. Journal of Coatings Technology and Research. Volume 17, Issue 4, 1 July 2020, Pages 1003-1012

View

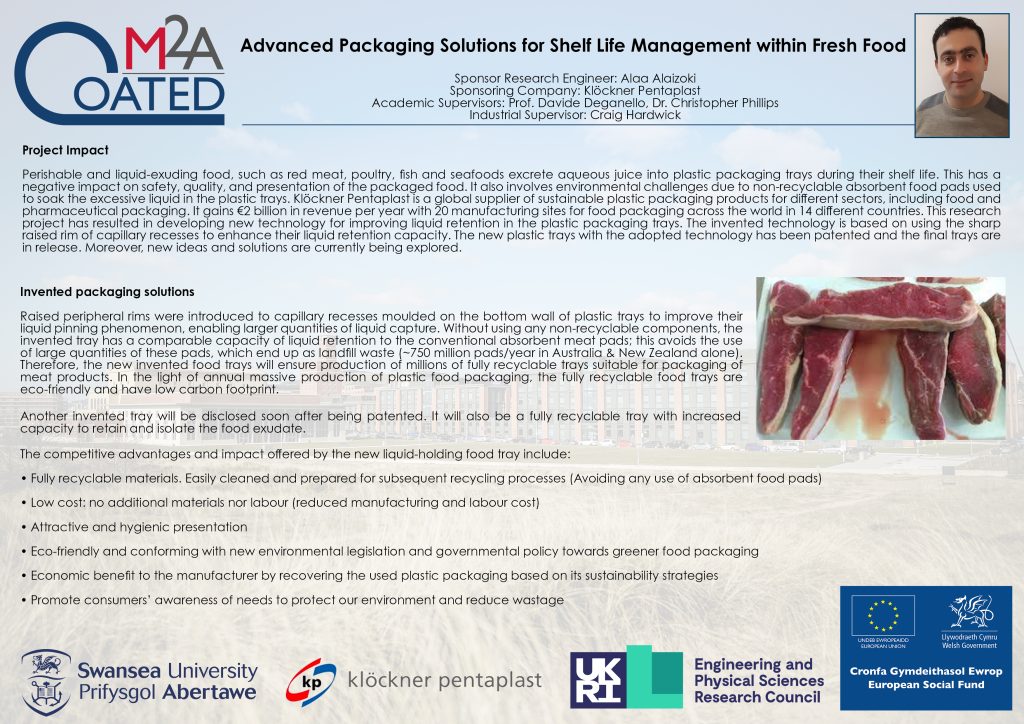

Alaa Alaizok Prof. Davide Deganello, Dr. Christopher Phillips Craig Hardwick. The rheological and physiochemical properties of meat exudate found in meat packaging trays (POSTER). 29th World Conference on Food and Beverages, 27th August 2020

James Grant Dr Amit Das Development of novel coatings for the reduction of high temperature oxidation in carbon steel tubes. 3rd Postgraduate Research Symposium on Ferrous Metallurgy. London, UK, 25th February 2020.

James Lelliot Dr Douglas Figueroa-Gordon, Prof Neil McMurray and Dr Elizabeth Sackett. Effect of microstructure and test parameters on hydrogen permeation in ultra-high-strength steels. 3rd Postgraduate Research Symposium on Ferrous Metallurgy. London, Uk, 25th February 2020.

Rebecca Dewfall Dr Soran Birosca and Dr Vladimir Basabe Blister formation in high strength steels during hot rolling (POSTER). 3rd Postgraduate Research Symposium on Ferrous Metallurgy. London, UK, 25th February 2020.

Caroline Norrish Dr Richard Underhill, Mr Carlos Llovo-Vidal, Prof Cameron Pleydell-Pearce and Prof Nicholas Lavery. Using rapid alloy prototyping to understand the effects of residual elements on a low alloy steel (POSTER). 3rd Postgraduate Research Symposium on Ferrous Metallurgy. London, UK, 25th February 2020.

Daniel Stewart Prof Andrew Barron Rapid, accurte metallic iron analysis for ironmaking materials (POSTER). 3rd Postgraduate Research Symposium on Ferrous Metallurgy. London, UK, 25th February 2020

Benjamin Cummings Patient specific bone phantom models for pre-surgical planning and education (POSTER) Future Materials Conference, Leeds, 17th December 2019

Liam Cotton Dr Shahin Mehraban, Dr Tom Dunlop and Professor Cameron Pleydell-Pearce An Industrial Study Of The Change In Behaviour Of Microporous Insulation In Teeming Ladles. UNITECR, Tokyo, Japan, 12-17th October 2019.

Gethin Llewellyn Low-Pressure Microcellular foaming of polypropelene through Chemical, Physical, hybrid foaming agents. SPE Foams, 2-3rd October 2019, Valladolid, Spain.

Potts, S.-J Phillips, C., & Claypole, T. High speed imaging of ink separation in screen-printing. Proceedings of 46th International Research Conference of Iarigai, Stuttgart, 15-18 September 2019. Page 8

Jack

Researchers from SPECIFIC and COATED M2A programme at Swansea University have collaborated with the University of Bath to make a groundbreaking advancement in thermal storage research, developing a new efficient material that is easily scalable and can be sized and shaped to fit multiple applications.

Rhodri

Rhodri Rees has completed his EngD researching advanced manufacturing techniques for medical applications. He originally joined Tata Steel on an apprenticeship before entering back into higher education studying for his bachelor’s and masters in mechanical engineering before taking on an EngD. He has enjoyed the range of opportunities offered including work with Calon Cardio and social aspects of being part of the cohort. He is now keen to continue sharing his technical abilities through teaching the future engineers.

Mathew

Mathew’s collaborative research between Swansea University and Tata Steel Colors has been based on the addition of alloying elements into widely utilised zinc-aluminium metallic coatings. The incorporation of magnesium into galvanising alloys has been steadily increasing across the sector, owing to its increased relative corrosion performance in given environments. His research has gone on to demonstrate where this newer coating could be used in the company’s product portfolio.

Rebecca

Working alongside Tata Steel, Rebecca’s research has focused on assessing the effects of chemical composition, temperature and time on oxide scale formation in an Ultra-Advanced High Strength Steel and a High Strength Steel. The ultimate goal of Rebecca’s research is to control oxidation rates and oxide scale morphology. This will allow Tata to adjust their manufacturing processes in order to reduce the material loss and improve the surface quality of the steels.

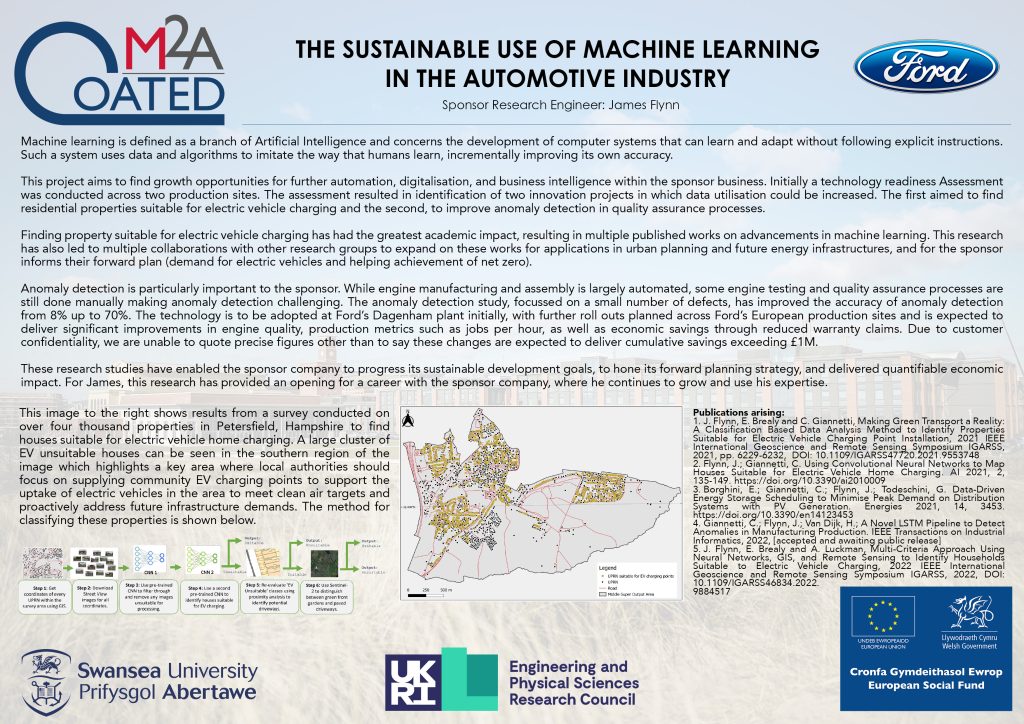

Tim

Tim’s research has been around development of methods that allow in-situ performance monitoring of organically coated steel products used in the construction sector. Currently, performance is often only estimated from laboratory-based accelerated testing, whereas live monitoring via sensors could allow far more accurate lifetime and maintenance data, facilitating early failure detection. If these technologies prove effective, then they will offer great insights into not only the viability of warranty accompanying the products, but into appropriate coatings selection based on environment and location.

David

David joined Swansea University in 2010 to study for a foundation degree in General Engineering and went on to successfully complete a degree in Chemical Engineering with first class honours, in 2015. Now studying for an Engineering Doctorate, researching “Application of Perovskite Solar Cells onto flexible steel substrate”, Dave shares his motivations and experiences of further study.

Catherine – DECODING DEGRADATION

Organically coated (painted) steel is exposed to many conditions in service from the varied inclement weather conditions around the world, UV exposure and pollution. With some coated steel products now coming with a 40 year warranty it is vital to understand how these products will perform. Catherine discusses the challenges of applying our advanced testing techniques to understand the performance of these coatings after accelerated and real life exposure tests.

Sara – PAINTING THE FUTURE

Organically coated (painted) steel is exposed to many conditions in service from the varied inclement weather conditions around the world, UV exposure and pollution. With some coated steel products now coming with a 40 year warranty it is vital to understand how these products will perform. Catherine discusses the challenges of applying our advanced testing techniques to understand the performance of these coatings after accelerated and real life exposure tests.

Phil – SKILLS TO SUCCEED

Despite having a 2:1 degree in chemistry Phil had failed to capitalise on his academic prowess. Phil tells us how his EngD has impacted his life and provides an insight into his new role with Akzo Nobel developing sustainable corrosion resistant coatings.

Ed – REVOLUTIONISING WATER TREATMENT

Billions of litres of water are used each year in industrial processes in applications ranging from heating and cooling through to applying lubrication. After the water has served its purpose it must be treated before being discharged back into the water system. Ed has been working on the problem of water treatment and applying novel green solutions for water treatment and tells us about the impact of his research.

Carlos – ATTRACTING TALENT TO SOUTH WALES

Carlos was fortunate enough to see an advert for the M2A scheme whilst in his home town in Spain. Realising the opportunity on offer, Carlos immediately applied to study for an MSc with the M2A and Tata Steel. After excelling in his masters Carlos has now gained employment within Tata Steel, choosing to remain in South Wales to build his career.

BLOODHOUND’S AERODYNAMIC DESIGN WITHOUT A WIND TUNNEL

Dr Ben Evans from Swansea University explains how Computational Fluid Dynamics has helped the designers to shape Bloodhound SSC.